Before manufacturing semiconductors, silicon must be converted into wafers. Wafer production includes ingot growth, ingot cutting and inspection, outer diameter grinding, slicing, rounding, surface grinding, etching, defect removal, polishing, cleaning and Inspect the packaging process; after the grinding process, a large amount of ultrapure water is needed to clean the suspended micro-particles or metal ion contaminants remaining on the wafer surface, resulting in CMP grinding waste and subsequent cleaning wastewater.

SP Solution:

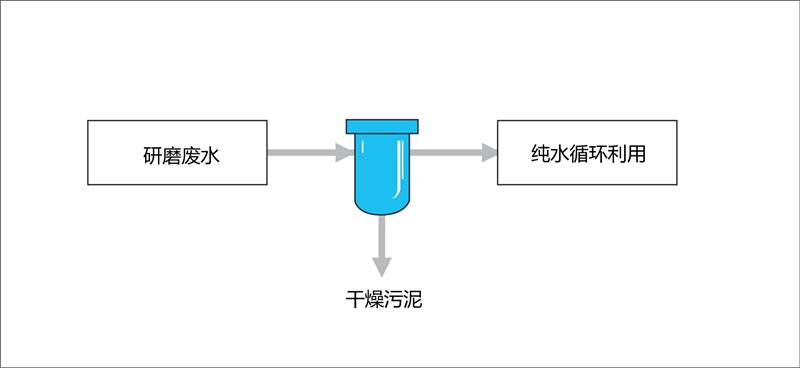

Improper treatment or direct discharge of wastewater from wafer cutting will pollute the environment, and failure to recycle the treated water will result in a waste of water resources. SP filtration technology solves the problems of traditional treatment methods that occupy a large area, add more chemicals, produce a large amount of sludge and unstable water quality. The supernatant liquid overflows to the middle water tank, the clean water is pressurized by the middle water pump and then further filtered, and then passes through a 10 micron bag filter, a 1 micron cartridge filter, an activated carbon adsorption device and a 0.2 micron precision filter at the terminal. Then it enters the terminal water tank, and sends the recycled water completely processed by the system to the ultrafiltration production water tank by the terminal water supply pump, which can directly enter the reverse osmosis device to continue the production of ultrapure water; the above process can also use a ceramic membrane microfiltration device to treat the supernatant liquid For filtration and concentration.

SP Advantages:

ØThe filter element has good strength, will not be damaged by metal cutting particles, and has a long service life.

ØAcid and alkali resistance, corrosion resistance, and good insulation properties.

ØHigh precision, high efficiency and no leakage.