The semiconductor industry is mainly used in the electronic machinery manufacturing industry. At present, there are mainly three types of wastewater from the semiconductor industry, namely fluorine-containing wastewater, copper-containing wastewater and ammonia-containing wastewater. Due to its complex water quality and high pollutant content, it has a greater impact on the environment. . Treating semiconductor production wastewater and making it actually reused in the factory not only effectively saves limited water resources, but also reduces sewage discharge, which has good economic benefits.

SP Solution:

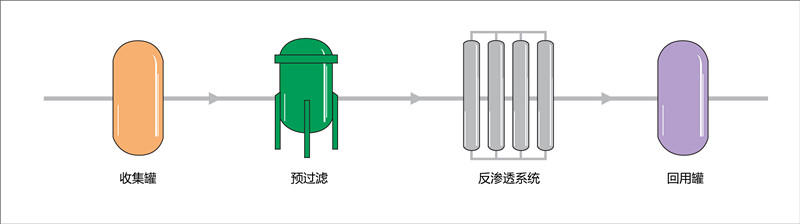

The semiconductor production process requires high requirements, covering various complex processes such as photolithography, precision cutting and grinding. The process of producing semiconductors will generate a large amount of waste water with many types of pollutants and complex components, which usually include a variety of heavy metal waste water, organic waste water and silicon. And fluorine waste, and the process cooling water of the semiconductor PCW system must be filtered for reuse. SP filtration separation technology can effectively filter out interfering particles and remove metal substances in wastewater.

SP Advantages:

High filtration precision, which can meet the precision of chip production.

Small footprint, centralized management and intelligent control.

High quality water, while removing phosphate and COD in wastewater.

Good resistance to chemical acid and alkali, long life and easy maintenance.