1. PTA's self-introduction

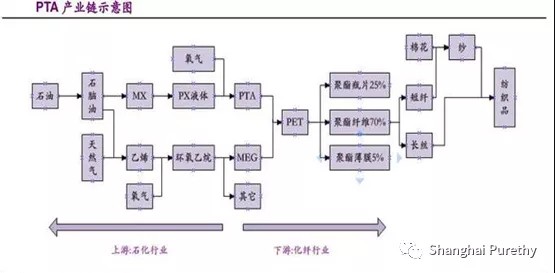

PTA is purified terephthalic acid (PureTerephthalic Acid). It is one of the important bulk organic raw materials. It is the main raw material for the production of polyester. The main purpose is to produce polyester fiber (polyester), polyester bottle flakes and polyester film. It is used in various aspects of the national economy such as chemical fiber, light industry, electronics, and construction, and is closely related to the level of people's living standards. At the same time, it is also the main raw material for the production of polyester. It can be directly esterified and polycondensed with ethylene glycol to obtain polyester, can also be made into engineering polyester plastic, and can also be used as a raw material for plasticizers and dye intermediates.

2. PTA's personality characteristics

It is a white powdery crystal at room temperature, non-toxic, flammable, and will burn when it comes in contact with air at a certain temperature. It will not melt when heated, and it will sublime at 300°C. If heated in a closed container, it can melt at 425°C. Easily soluble in organic solvents, but hardly soluble in water. Esterification reactions can occur, and halogenation, nitration and sulfonation reactions can also occur under strong conditions.

3. The birth process of PTA

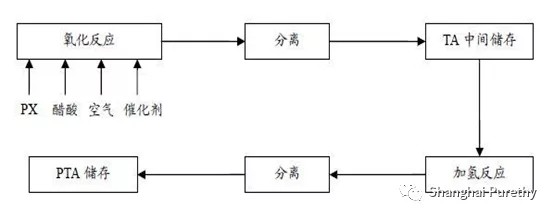

The PTA production process can be divided into two parts: oxidation unit and hydrofining unit. The raw material p-xylene uses acetic acid as a solvent, and is oxidized into crude terephthalic acid (CTA) by air under the action of a catalyst, and then is crystallized, filtered, and dried into a crude product; the crude terephthalic acid is hydrogenated to remove impurities, and then After crystallization, centrifugal separation, and drying, it becomes the finished product of PTA.

4. PTA filtering link

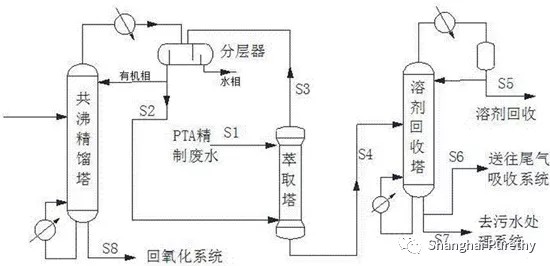

The production process of the PTA refining unit needs to use a large amount of deionized water as a solvent, and most of the deionized water leaves the main process flow in the form of mother liquor. This refined sewage has a large flow rate, a high chemical oxygen demand (COD), a high solid content and is difficult to treat specialty. Since the mother liquor contains reaction by-products, it is necessary to set up a mother solid recovery unit to recover the organic matter in the mother liquor to reduce resource consumption.

Filtration in mother liquor recovery: The metal powder sintered filter element is used to recover TA (terephthalic acid) and other organics in the mother liquor, which can not only reduce the unit consumption of PX (para-xylene) in the system, but also reduce the COD content in the wastewater.

Filtration in wastewater treatment: The COD concentration of PTA wastewater is high, and some of the acidic substances are substances containing benzene rings. The temperature of wastewater is high and the pH changes greatly. Membrane separation technology is commonly used in wastewater treatment. Setting up a filter in front of the reverse osmosis membrane separation device can effectively prevent damage to the filter membrane, while also improving the filtration efficiency and protecting downstream equipment.

Filtration in the production process: In the PTA production process, the solid-liquid separation is very important. The solid-liquid separation in the oxidation section is to remove the acetic acid solution in the TA slurry to ensure the production requirements of the hydrorefining stage; The purpose of solid-liquid separation in the refining stage is to remove PT acid and filter to obtain high-purity terephthalic acid.

Pinkang Environmental Protection is committed to providing tailor-made filtration separation and purification solutions for global industrial customers. Welcome to contact us.