String Wound Cartridge is a kind of depth filtration with the micron rating decided by the wound pattern and wound density of filament yarn. Its pore is bigger outside and smaller inside. It is mostly used in low viscosity and low impurity liquid, and also suspended particular materials. With different types of filament media, the cartridges could meet different applications like: water treatment, food & beverage, organic solvent, plating solution in electronics industry, petrochemical industry, hydraulic liquid, lubricant and so on.

Advantages

Honeycomb structure makes it higher efficiency and better accuracy.

Big flow rate and dirt holding capacity.

Both spirals welding and straight welding are available, which could be easily used in high psid application.

Good chemical compatibility based on different filtration materials.

Different sizes (length and diameter) are available to meet different filtration area requirements.

Applications

Automobile, copper foil, electronic industry, fine chemicals, papermaking, food medicine, coatings, petrochemical various micro-content impurities liquids

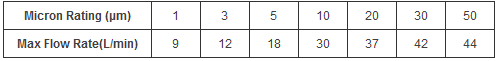

Data Sheet

Note: The cartridge tested is 250mm, with differential pressure 0.02 MPa, Test media is water, and room temp. For flow rate of other length, it is based on this.

Max Pressure: ≤ 0.5 Mpa Max Pressure Drop≤ 0.2 Mpa

Max Temp.: PP material with PP core ≤ 70 deg C; PP material with SS core ≤ 90 deg C; Breach Cotton material with SS core ≤ 120 deg C

Spec.: Length: 5″, 10″, 20″, 30″, 40″, 50″, 60″, 70″, 80″(often used in water treatment of power plant)

OD: 60—115mm (±1mm) ID: 28, 30 mm (±1mm)

Note: We can tailor made for some non standard products if qty. is big.

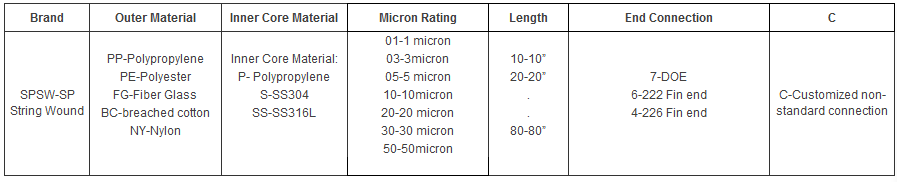

Order Code