The SP hygiene-grade filter has the barrel fully made of superior 304 or 316L stainless steel. Each filter is a product carefully made with strictly selected materials, with streamlined design free from any crack ensured. The filter has properly designed surface and maximum corrosion resistance to satisfy the quality standard for prevention of bacterial pollution. The unique structure of the hygiene-grade filter barrel has no dead corner on the internal or external surface, and can be fully demounted for washing. Besides, the filter can be easily operated.

Advantages

We provide filters of different flow according to customer's requirements for different material, pore diameter, length and quantity of cartridge. Filter applies reasonable fluid mechanics technique, design, manufacturing, inspection and acceptance in accordance with GB150-1998.

Applications

Solid- liquid separation of Petroleum, Chemical, Machinery, Metallurgy, Textile, Printing and Dyeing, Electroplating, Medicine, Food and other industries.

Data Sheet

| Internal surface: | The internal surface has undergone mirror polishing or electrolytic polishing treatment. |

| External surface: | The external surface has undergone matting, mirror polishing or electrolytic polishing treatment. |

| Material of the barrel structure: | 304 or 316L |

| O-ring: | Food-grade silicon rubber O-ring, VITION, PTFE. |

| Way of locking: | Clamp, hygiene-grade sleeve or bolt for fast installation and demounting |

| Maximum operating pressure: | 25kgf/cm2 |

| Maximum operating temperature: | 80℃ |

| Hydraulic test: | Each filter has undergone a hydrostatic test under up to 1.25 times of the design pressure. |

Photos

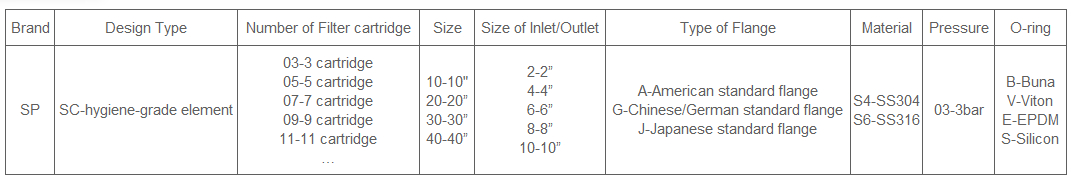

Order Code

For example: SP SC 03102AS403B