The metal working fluid plays the role of lubricating, cooling, rust-proofing and cleaning the tools and workpieces in the machining process. It is mixed with metal impurities, microorganisms in the water, and grinding wheel ash in the grinding fluid during the machining process, which will cause the machining accuracy Influence. Currently commonly used cutting fluids include cutting oil, soluble cutting oil, semi-synthetic cutting fluid and synthetic cutting fluid. In the machining process, it plays a role of lubrication, cooling, rust prevention, and cleaning of the tool and the workpiece. Metal impurities, microorganisms in the water, and grinding wheel dust in the grinding fluid are mixed during the machining process, which will affect the machining accuracy. Currently commonly used cutting fluids include cutting oil, soluble cutting oil, semi-synthetic cutting fluid and synthetic cutting fluid.

SP Solution:

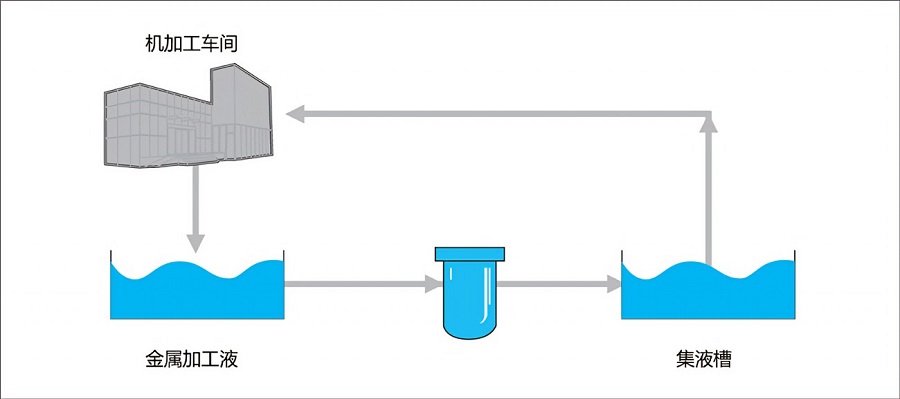

According to different working conditions, processing fluids of different properties are produced, and a suitable filter system can effectively reduce the loss of tool machines, extend the service life of the equipment, and greatly improve production efficiency. Recycling is beneficial to environmental protection and reduces the cost of cutting fluid.

SP Advantages:

ØHigh filtration accuracy and improved processing accuracy.

ØSatisfy the needs of intermittent operation and various small batch production, especially suitable for the separate filtration of the cutting fluid of a small-scale single machine tool.

ØThe magnetic filter developed by SP can automatically recover magnetic materials for magnetic particles.

ØSP filtration system is often used in processes such as emulsion recovery and waste purification treatment.