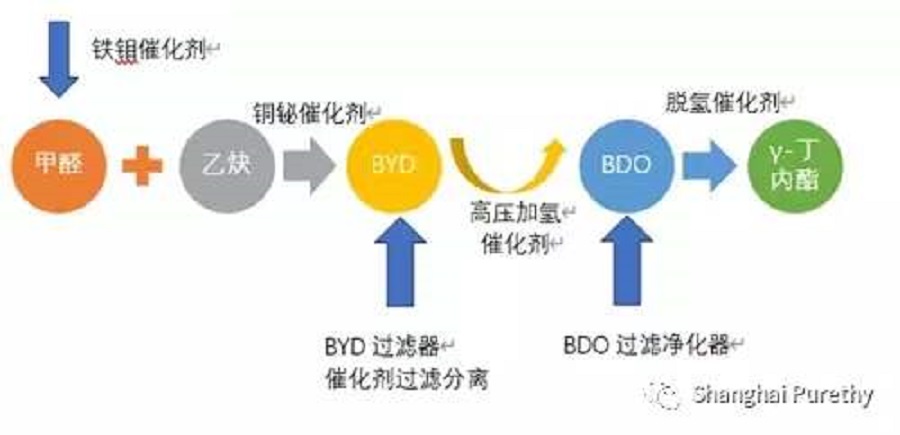

BDO production process is that acetylene and formaldehyde pass through the catalyst slurry layer in countercurrent, and react at 93°C, 0.1 MPa and the action of a catalyst. The stirrer and the acetylene gas entering from the lower part of the reactor can keep the catalyst in suspension. After the generated BYD is separated from the catalyst through the built-in filter, the catalyst remains in the reactor. After filtration, the crude BYD filtrate enters the BYD purification unit to remove methanol and formaldehyde, and the purified BYD solution enters the hydrogenation section. BYD hydrogenation is carried out in two fixed-bed reactors connected in series, and 99% of the hydrogenation reaction is completed in the first reactor. The crude BDO solution after hydrogenation is concentrated, rectified, and filtered to remove impurities to obtain a pure BDO product.

SP Solution:

Filtration is an important process in the BDO production process. It can filter and separate catalysts, filter and purify materials, etc., in various forms. For example, BYD filter, hydrogenation catalyst filter, etc. The choice of catalyst filter determines the efficiency and recovery rate of filtration. Pinkang Environmental Protection has solved a series of practical problems such as difficulty in recovery and filtration for customers. The catalyst interception in the reactor reduces the transmission process, reduces energy consumption, catalyst loss, and improves catalyst utilization.

SP Advantages:

ØOne-piece design, compact structure, reducing floor space.

ØFully automatic control, airtight operation.

ØThe filtering equipment is automatically cleaned, with high efficiency, and the filtering accuracy can be below 1um.

Ø It has good chemical resistance, high temperature resistance, and is suitable for various harsh production environments.