Leakage of the lubrication system, inadequate sealing, long-term thermal load of the oil, open oil storage, etc. The moisture and gas in the air seep into the oil, resulting in water and gas in the lubricating oil. Due to the leakage of the lubrication system, the particulate dust in the air enters or the system wear dust falls off, and the lubricating oil works for a long time under high temperature and water content, which will inevitably cause part of the oil to lyse and deteriorate to precipitate a colloidal substance.

SP Solution:

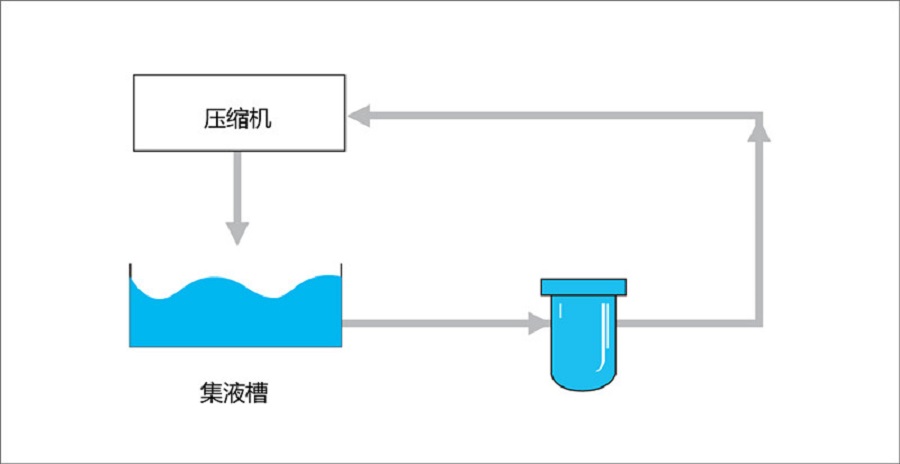

The lubricating oil coalescing skid uses high-efficiency coalescing filter elements to remove the water in the oil. These systems can quickly remove the free water entrained in the lubricating oil, effectively replacing the previous centrifugal equipment. Excellent technical effect, easy to use, and lower maintenance cost. After the lubricating oil passes into the filter, it is filtered through the wire mesh from the inlet, enters the filter core and flows out through the outlet to filter out particulate impurities. For highly viscous oils, a scraper filter system can be used to allow the metal sheets to rotate between each other to scrape off the dirt.

SP Advantages:

ØCan achieve continuous production filtration

ØGood coalescence and separation effect, special filter element material, thorough dehydration

ØWide range of applications and strong adaptability

ØEffectively solve the problems of blockage, oil adhesion to equipment, etc.