The CIP cleaning system is widely used in the food, beverage, wine, pharmaceutical industries, etc., not only to clean the machine, but also to control microorganisms. The degree of equipment pollution, the nature of the contaminants and the production process of the product are important reasons for determining the cleaning effect. If the CIP conditions are not determined according to their characteristics during cleaning, it is difficult to achieve the ideal purpose or lead to defects such as high cleaning costs.

SP Solution:

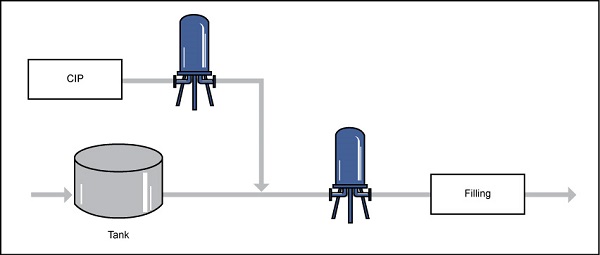

The CIP system is connected with all processing equipment into a cyclic cleaning circuit, and the system adopts fully automatic control. The fully automatic CIP cleaning system is suitable for in-situ cleaning of material pipeline equipment in dairy plants, breweries, beverages and general food plants. The CIP in-place cleaning system has low economic operation cost, compact structure and small floor space. It is easy to install and maintain. It can effectively clean the production equipment such as cylinders, containers and pipelines on-site. The entire cleaning process is in closed production. Equipment, tanks, containers and pipelines are running, which greatly reduces the chance of secondary pollution.

SP Advantages:

ØCompact design, easy installation, maintenance and debugging, stable and reliable performance.

ØModular structure composed of functional blocks can be operated by manual control, automatic control, touch screen, etc., which is easy to operate.

ØEffectively remove residues and prevent microbial contamination.

ØGood cleaning and filtering effect, which can improve production capacity.

ØReduce cleaning cost, less water, cleaning agent and steam consumption.

ØSafe and reliable, the equipment does not need to be disassembled.