Catalysts occupy an extremely important position in the modern chemical industry. According to statistics, about 80% to 85% of chemical production processes use catalysts to speed up the reaction rate and improve production efficiency. However, expensive waste catalysts increase the cost of the company and are filtered and recycled. Deactivated spent catalyst has become an inevitable move.

SP Solution:

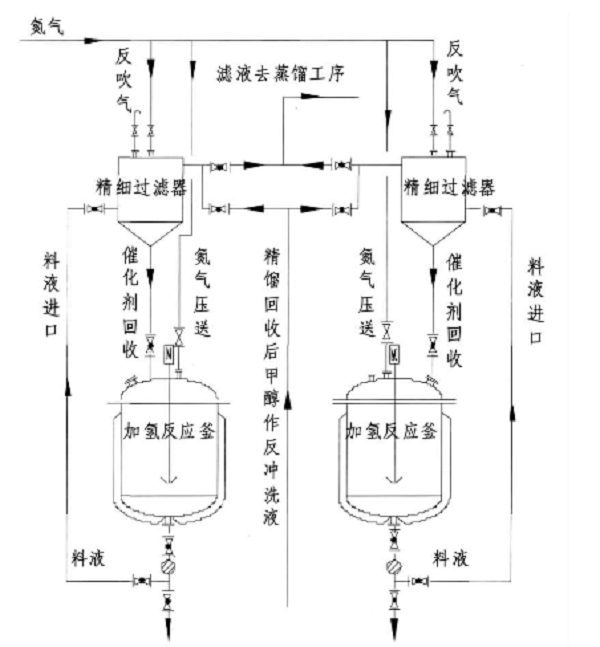

The partition and filter element in the fine filter separate the filter cylinder into a water inlet cavity and a water outlet cavity. The medium containing solid suspended particles enters the water inlet chamber of the filter through the water inlet. Under a certain pressure, the water passes through the micropores in the filter tube of the filter, and is discharged from the water outlet through the pipeline to the user's place of use. The suspended matter whose particle diameter is larger than the pore precision of the filter tube is trapped on the outer surface of the filter tube to form a filter cake. As the running time increases, the filter cake thickens, resulting in a decrease in the filter flow rate and a higher pressure difference. Bigger. In order to prevent the filter cake from being crushed and clogging the filter tube, it must be backwashed. Under the dual action of pressure gas purging and backwashing fluid, the filter cake is destroyed and forcibly discharged into the sewage tank.

SP Advantages:

ØReduce costly material loss

ØImprove the quality of medical products

ØReduce waste discharge and meet green environmental protection standards

ØReduce maintenance cycle and cost

ØReduce energy consumption, increase recovery rate and purification rate