The sterilization filter mainly uses a microfiltration filter element with a large specific surface area and a filtration accuracy of 0.22μm or more. It is used to prevent impurities, harmful bacteria and microorganisms in the air from entering the tank, production line, sterile room, etc., causing water quality and products. And the changes of the sterile room environment can meet the technological needs of the medical and pharmaceutical industries.

SP solution:

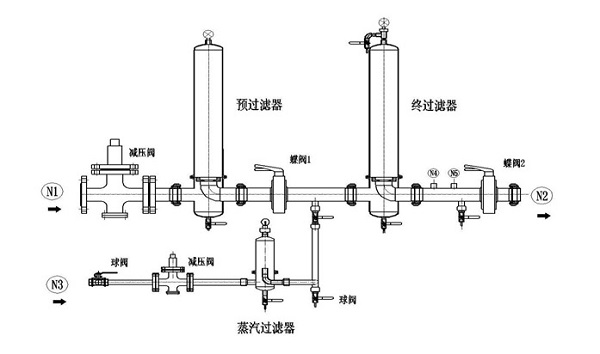

The sterilization filter generally adopts a cross-hung type, with horizontal entry and exit. The multi-core filter can be designed as a floor-standing type. Some applications are divided into pre-filter and fine filter according to actual needs. The air flows through the filter element from the outside to the inside. The compressed air entering the sterilization filter must first pass through at least a three-stage precision filter and dryer. For oil removal, water removal, and dust removal, the oil mist concentration should be ≤0.01PPM, otherwise it will affect the life of the sterilization filter element and fail to achieve the expected sterilization effect.

SP product advantages:

ØPrecise filtration accuracy and high strength.

ØLarge flux and high processing efficiency.

ØThe filter material has strong hydrophilicity or hydrophobicity.

ØThe sterilization effect is good, and it can effectively intercept the pollutants of the size of the bacteria.