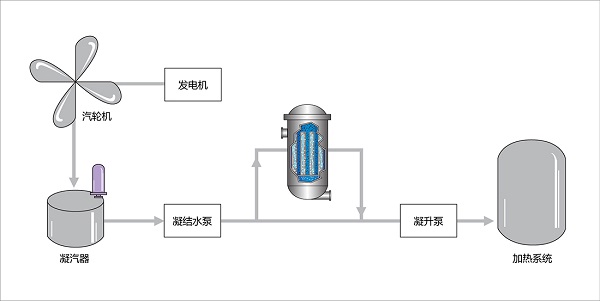

The condensate in power plants includes steam turbine condensate and various drains. In addition to thermal power plants, there is condensed water returned from heat users. The condensate pool and make-up water constitute boiler feed water; untreated condensate water generally contains a certain amount The impurities come from the leakage of the condenser, the corrosion of the metal of the thermal equipment and the remaining impurities in the boiler feed water; most of the suspended matter contained in the condensate is insoluble, such as iron oxide, iron hydroxide and other corrosion products. They cannot be removed by ion exchange. If the corrosion products in the condensed water are not treated, they will be sent to the boiler and deposited on the parts with high heat load to form iron scale, which will affect the heat transfer and safe operation of the furnace tube. Influence.

SP Solution:

In view of the fact that most of the impurities in the condensed water are very small suspended solids and colloids, very fine powdered substances are used as the filter medium to remove the impurities in the condensed water. The corrosion products in the condensate are mainly Fe3O4 and Fe2O3. Magnetic filters can also be used to remove metal ions. For harsh working conditions, microporous filters can also be used for precision filtration.

SP Advantages:

ØHigh filtration accuracy and fast transition speed.

ØLess adsorption and no media shedding.

ØResistant to acid and alkali corrosion and high temperature.

ØGood airtightness and no leakage.