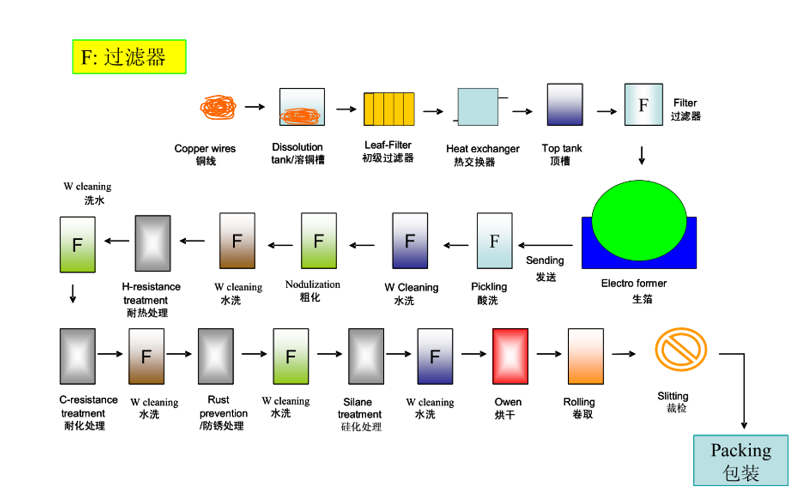

Electrolytic copper foil is an important material for the manufacture of copper clad laminate (CCL) and printed circuit board (PCB). In today's rapid development of the electronic information industry, electrolytic copper foil is called the "neural network" of electronic product signal and power transmission and communication. There are three main processes in the production process: solution-forming foil, surface treatment and product slitting. Since the production of electrolytic copper foil has very strict requirements on the cleanliness of its electrolytic solution (copper sulfate solution), many filtration systems and liquid pumps have been repeatedly used in the previous production process. Can fundamentally control product quality and reduce production costs.

SP Solution:

A large number of filters are used in the production process to remove impurities in the fluid.

1. The raw foil process is one of the most critical links in the production of copper foil. The copper sulfate solution is required to be pure, free of impurities, and uniform and stable in composition. Adsorption of particulate impurities on the surface of the copper foil will cause quality defects such as rough surface, penetration points and pinholes. Therefore, the solution must be purified through a high-precision filter.

2. The electrolysis process is very sensitive to organic impurities. Organic impurities in copper foil electrolysis process mainly include glue in solution

A small drop of lubricating oil may cause 8-12 hours of waste in the electrolysis system. Therefore, filters must be used to remove oil and impurities to ensure production efficiency and quality.

SP Advantages:

ØHigh filtration accuracy, uniform filter element pore size;

ØSmall filtration resistance, large flux, strong dirt interception ability and long service life;

ØThe filter element material has high cleanliness and no pollution to the filter medium;

ØResistant to chemical solvents such as acids and alkalis;

ØHigh strength, high temperature resistance, and the filter element is not easy to deform.