In lithography, flexographic printing, or gravure printing, it is a challenge to achieve printing consistency regardless of whether the ink has thermal offset. Ink color and ink particles are two important factors, which is a time-consuming adjustment operation. This is especially important for some inks with higher color matching requirements. There are many sources of ink pollution in production. Due to complex production, there are various types of impurities, including fiber, solid, semi-solid, etc. Normally, the circulatory system needs to completely eliminate pollutants. The filter of the system removes contaminants while ensuring that ink particles are retained, maintaining the concentration and color of the pigment.

SP Solution:

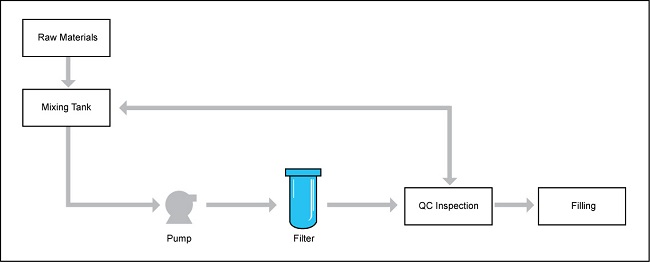

The typical ink manufacturing process requires continuous recycling and multiple quality checks to achieve product color and grinding specifications.

Depending on the color of the ink and the particle size of the pigment, single-stage or multi-stage filtration may require the use of a series of filters. The filter trolley system is an integrated design that combines trolley, basket, bag, cartridge filter and membrane system. The system structure is light and handy, so that the movement and performance are flexible, and it is easy to operate. For small and medium-sized ink companies, the filter trolley system will become the first choice.

SP Advantages:

ØSuitable for filtering viscous media with high filtering accuracy.

ØAutomatically flush and scrape out the remaining ink.

ØPigment separation effect is good.