The waste water generated in the coating process is the main waste water of the automobile manufacturing industry. The coating process is the most serious process of water pollution in the whole process of automobile manufacturing. The coating wastewater contains resin, heavy metal ions, petroleum, PO43-, organic solvents and other pollution. It has a high CODCr value. Waste water is generated in the process of pre-cleaning, degreasing and degreasing water washing, surface conditioning, phosphating and phosphating water washing, electrophoretic primer and water washing, spraying paint, top paint, and finishing paint. These processes require a large amount of fresh water to be filtered. Reuse can effectively avoid serious waste of water resources.

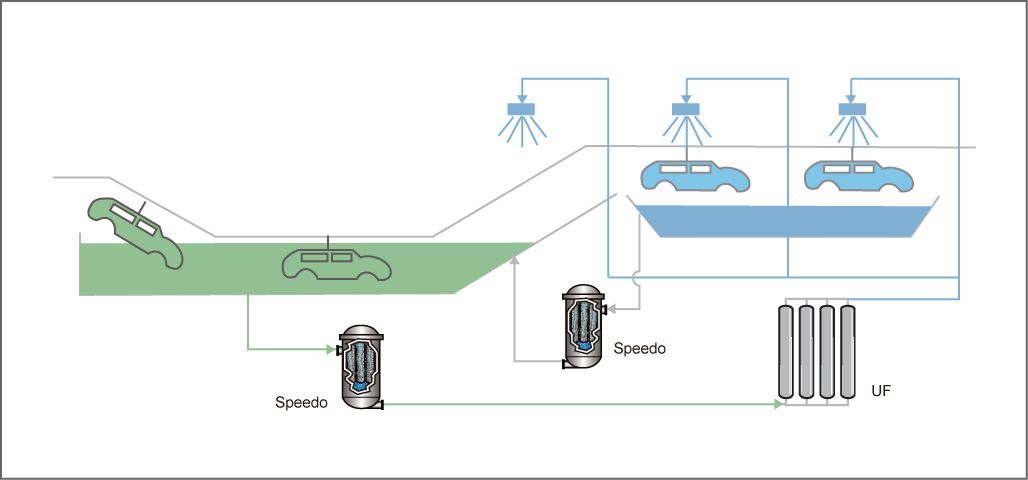

SP Solution:

The circulating water continues to circulate through the equipment outside the pool to collect paint mist. The suspended paint residue formed is solid waste and needs to be filtered and removed in time, otherwise the suspended paint residue will settle and cause the entire circulation system to paralyze. SP optimized mechanical design, can achieve magnetic absorption of metal particles, design continuous filtration without manual intervention, and have a good filtering effect on suspended paint residues of different particle sizes.

SP Advantages:

The processing capacity is large, and it can work continuously.

The removal effect is good, and the spraying agent will not adhere to the inside of the cylinder.

It has a wide range of applications and has a good treatment effect on oily and metal-containing wastewater.

The support is strong, not easy to deform, easy to clean and easy to replace.