In the degreasing process, the removed dirt will gradually accumulate in the tank liquid, and the degreasing efficiency of the degreasing agent in the degreasing liquid is usually proportional to the cleanliness of the solution. In order to obtain a satisfactory degreasing efficiency and prolong the life of the tank liquid, it is necessary as soon as possible Removal of dirt from the solution is necessary for the circulation of the tank liquid in a closed circuit; at the same time, it is necessary to avoid clogging of nozzles and pipelines or even pump damage, and reattachment of impurities to the workpiece, which affects the quality of coating.

SP Solution:

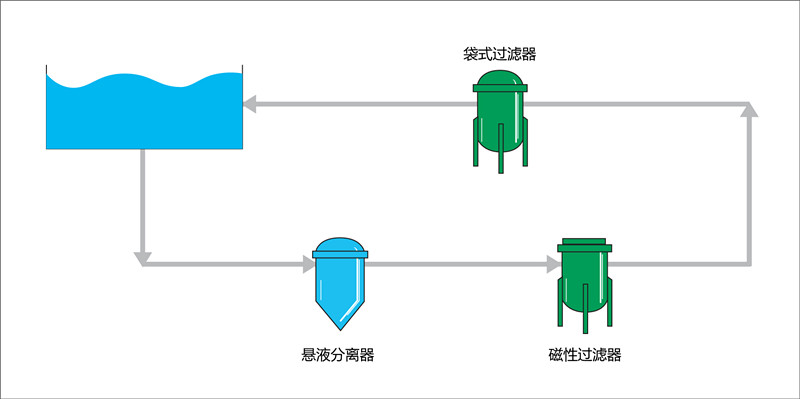

The automobile coating process is generally divided into the surface treatment of the metal before coating (pretreatment technology) and the construction process of the coating. Surface treatment mainly removes oil, dust, rust on the surface of the workpiece and the removal of the old paint layer during repairing operations to improve the surface state of the workpiece; the impurities adhering on the surface of the workpiece are left in the degreasing tank after pre-degreasing and degreasing procedures. The liquid can be recycled after filtering and removing impurities and separating oil and water.

SP Advantages:

ØAutomatically remove ferromagnetic powder and particles and iron oxide.

ØCan capture small and weak magnetic impurities.

ØSuitable for heavy pollution and high cleanliness requirements.

ØThe initial investment cost is low, no need to change the equipment, directly replace the filter bag.

ØThe filtration efficiency is high, the dirt holding capacity is large, and the consumables and labor costs are quickly and effectively reduced.